Flat roof deck construction is a popular building design choice, prevalent in commercial, industrial, and even residential settings. This construction involves creating a roof with a minimal slope to facilitate rainwater drainage. The process typically includes the installation of a waterproof membrane, insulation for energy efficiency, and a protective roofing layer.

If you’re in need of construction estimate services, simply go to homepage or follow the links below:

| Services | Links |

|---|---|

| Detailing Services | Link |

| Building Information Modeling | Link |

| General Contractor | Link |

| Subcontractors | Link |

| MEP | Link |

Key Components of Flat Roof Construction

1. Waterproof Membrane

- Materials: Asphalt, EPDM, PVC, TPO

- Purpose: Prevent water penetration into the building structure.

2. Insulation Layer

- Material Options: Mineral wool, expanded polystyrene (EPS), polyurethane foam

- Function: Enhance energy efficiency by preventing heat loss.

3. Roofing Material

- Options: Asphalt, gravel, reflective coating

- Role: Protect the membrane and provide additional weather resistance.

Cold Flat Roof Construction

Definition

A cold flat roof, also known as an ‘unvented roof’ or ‘cold deck roof,’ lacks insulation between the structural deck and waterproofing layer.

Ventilation

Ventilation is crucial to prevent condensation, and insulation may be placed below the roof deck, inside the building, or as a separate layer on top of the waterproofing.

Insulation Materials

Materials such as mineral wool, EPS, or polyurethane foam can be used, with the choice depending on factors like climate and building codes.

Considerations

While cost-effective, proper design and installation are essential to prevent energy inefficiency and condensation issues.

Warm Flat Roof Construction

Definition

In warm flat roof construction, insulation is placed above the roof deck and beneath the waterproofing layer.

Vapor Barrier

A vapor barrier beneath the insulation prevents warm, moist air from causing condensation within the roof assembly.

Insulation Materials

Options include EPS, extruded polystyrene (XPS), or polyisocyanurate (PIR), selected based on factors like climate and building codes.

Advantages

Warm flat roofs can reduce energy costs and mitigate condensation problems, but meticulous design and installation are critical.

Factors to Consider Before Starting Your Roofing Project

1. Structural Safety

Ensure your existing flat roof can support the additional weight of the deck, furniture, and occupants. Reinforcements may be necessary.

2. Check Local Building Codes

Consult with local experts to understand regulations, permits, and building codes. Non-compliance can lead to fines and construction halts.

3. Budget Considerations

Plan your budget carefully, accounting for design, materials, labor, permits, and unexpected expenses.

Rooftop Deck Materials: Which Material is Best?

Wooden Decks

Timeless and warm, wooden decks (cedar, redwood, or pressure-treated pine) suit various architectural styles.

Concrete Decks

Sleek and modern, concrete decks offer customization options with stamped or stained patterns, providing sturdiness.

Paver Decks

Elegant and stone-like, paver decks elevate the aesthetic with easy repair options for damaged pavers.

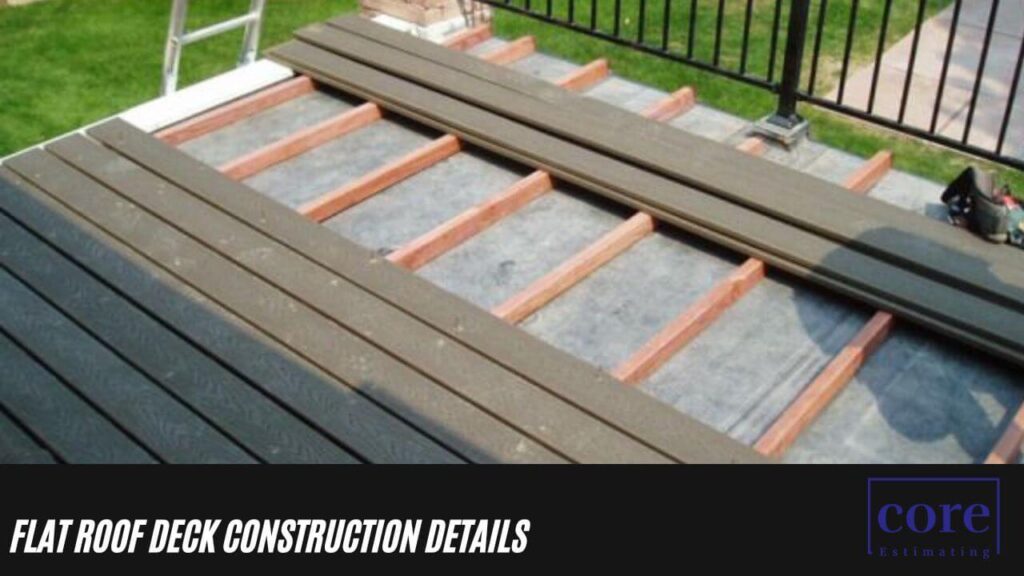

Deck Materials for Flat Roof Construction

A crucial component of flat roof construction is the deck, serving as the structural foundation that supports various loads. Choosing the right material for the deck is essential to ensure structural integrity, longevity, and proper adhesion of the roofing system. Here are common deck materials and their specifications:

1. Timber Boarding

Characteristics:

- Material: Softwood timber.

- Requirements:

- Naturally durable species or preservative-treated (BS EN 599-1:2009).

- Minimum thickness of 19mm.

- Double nailed at each joist.

- Staggered joints for strength.

- Edges aligned with joists or noggins.

2. Plywood

Characteristics:

- Material: Marine-grade plywood suitable for external use (BS EN 636).

- Requirements:

- Minimum thickness of 18mm (spanning up to 600mm).

- Double nailed at each joist.

- Staggered joints.

- Edges aligned with joists or noggins.

- 3mm expansion gaps between boards.

3. Oriented Strand Board (OSB)

Characteristics:

- Material: Wood panel composed of timber strands (BS EN 300: Part 3: 1992).

- Requirements:

- Minimum thickness of 18mm (spanning up to 600mm).

- Double nailed at each joist.

- Staggered joints.

- Edges aligned with joists or noggins.

- 3mm expansion gap between boards.

4. Concrete

Characteristics:

- Types: Cast in situ (poured on site) or pre-cast units.

- Surface Requirements:

- Free from ridges and hollows.

- Smooth base achieved with a sand and cement screed.

- Fall Creation:

- Achieved through proprietary products or sand and cement screed.

- Covering Limitations:

- Covered only by non-bonded or partially bonded roof coverings.

5. Woodwool Slab

Characteristics:

- Composition: Rigid timber and cement-based panels.

- Thickness: Minimum 50mm.

- Compliance: Conforms to BS EN 13168.

- Reinforcement: Optional for long spans.

6. Profiled Metal Decking

Characteristics:

- Material: Galvanized steel or aluminum.

- Advantages:

- Lightweight construction suitable for long spans.

- Reduces load on the building’s structure.

- Considerations:

- Does not provide a continuous surface.

- Suitable only when supporting timber deck or rigid insulation.

- Must be covered with a bituminous or polymeric membrane for use in cold roof design.

Conclusion

With these considerations and material options, you’re well-equipped to embark on your flat roof construction and rooftop deck project. Prioritize safety, adhere to local regulations, manage your budget, and select materials that align with your aesthetic preferences and practical needs.